CASES

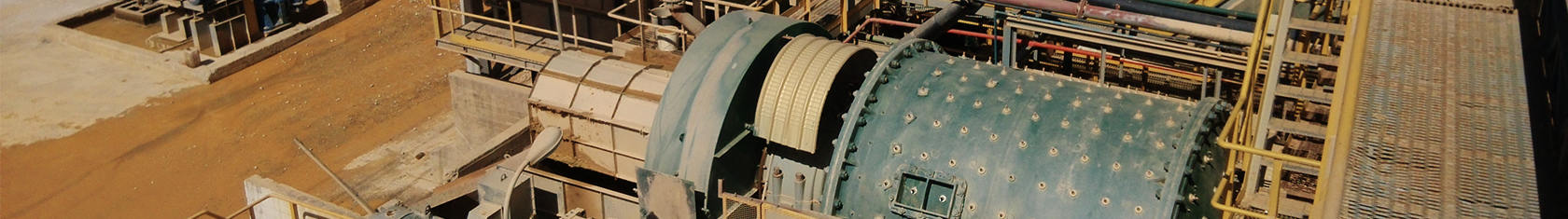

Copper Beneficiation Plant

1. Beneficiation Technologies

Mineral Crushing, Heap Leaching, Extraction and Electrolysis

2. Additive

-----Concentrated sulfuric acid

(the concentration is 98% and it is to be used to produce 50g/l dilute sulfuric acid)

----- Extraction agent

(the price is about 200USD/TON)

3. The Processing Flow

Raw oxidized minerals are firstly crushed to 0~25mm, then they will be extracted by 50g/l dilute sulfuric acid and CuSO4 liquid can be produced. Finally, producers will get pure copper by electrolysis.

4. The Chemical Reaction

H2O-2e ——0.5O2+2H+

Cu2+ +2e——Cu

Cu2+ + H2O —— Cu + 0.5O2 + 2H+

5. Advantages

1. Low investment cost

2. Compared with Pyrometallurgy, the production cost is low.

3. No waste gas and no waste water

4. The extraction agent is easy to get and the price is quite low.

Fill in this form or click the service online, all questions will be answered.